Can ends

-

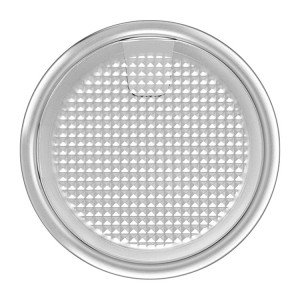

Aluminum FA Full Aperture Easy Open End 401

Packfine aluminum FA full-aperture beverage cans are designed to create a more pleasant consumption experience.

By allowing consumers to remove the entire lid, the end of the beverage can is transformed into a cup, and beer drinkers are attracted by more closely imitating the pouring of the tap, and all the taste and aroma of beer hit the drinkers’ senses. The design also makes the supply of beer, craft beer, and low-carbon products simple and efficient.

Aluminum FA Full Aperture Easy Open End 401 is mainly used for nuts, candy, coffee powder, milk powder, etc.

Diameter: 98.9mm/401#

Shell Material: Aluminum

Design: FA

Application: Nut, Candy, Coffee Powder, Milk powder, Nutrition, Seasoning, etc.

Customization: Printing.

-

Aluminum FA Full Aperture Easy Open End 603

The inner coating of the full aperture can end meets the requirements of health and safety. The products packaged with it are easy to carry and use, can adapt to different climatic conditions, and have good waste disposal. The purchase of waste can end compacts that can be recycled. Large diameter full aperture can end is more suitable for food, such as nuts, candy, milk powder, etc. Consumers can choose different diameter can end according to different contents.

Diameter: 153mm/603#

Shell Material: Aluminum

Design: FA

Application: Nut, Candy, Coffee Powder, Milk powder, Nutrition, Seasoning, etc.

Customization: Printing.

-

Tinplate FA Full Aperture Easy Open End 202

Packfine’s Tinplate FA full aperture can end is completely sealed, light tight, and heat resistant. This makes them very suitable for all kinds of food. As you expected, all our can ends meet the strict requirements of the EU and FDA. Canned food has existed in the world for more than 200 years. When you think of it, it is logical because it can keep food longer and protect it from moisture, insects, bacteria, and other hazards.

Diameter: 52.5mm/202#

Shell Material: Tinplate

Design: FA

Application: Dairy products, Nut, Candy, Spices, Fruit, Vegetable, Seafood, Meat, Pet food, etc.

Customization: Printing.

-

Tinplate FA Full Aperture Easy Open End 401

Our tinplate FA full aperture can end are versatile. They are suitable for beverage products as well as for food. These tinplate can ends are ideal for cheese in brine in particular.

For different types of usage, Packfine can recommend you the right type of tinplate and proper lacquer. All lacquers we use are approved by relevant authorities. There is a sealing layer inside, which can enhance the sealing of cans. Lid with pulling ring, easy to open. Well-treated surface and smooth edges without hurting hands.

Diameter: 98.9mm/401#

Shell Material: Tinplate

Design: FA

Application: Dairy products, Nut, Candy, Spices, Fruit, Vegetable, Seafood, Meat, Pet food, etc.

Customization: Printing.

-

Aluminum FA Full Aperture Easy Open End 307

The whole aluminum FA full aperture can end of the can is removable, which can be turned into a drinking bottle without separate glassware. The full aperture can end will be more sustainable. Compared with traditional beverage ends, the amount of metal used in cans is reduced by 10%, making cans more environmentally friendly. Full-aperture means they can be used to can everything from beer to food, such as Nut, Candy, coffee Powder, Milk powder, Nutrition, Seasoning, etc.

Diameter: 83.3mm/307#

Shell Material: Aluminum

Design: FA

Application: Nut, Candy, Coffee Powder, Milk powder, Nutrition, Seasoning, etc.

Customization: Printing.

-

Tinplate FA Full Aperture Easy Open End 209

FA full aperture cans end (round, quarter bar, oval, pear-shaped) made of tinplate are containers that have a variety of uses such as tuna, tomato paste, vegetables, fruits, juice, etc., and also for dry packages, such as coffee powder, milk powder, grains, and nuts. We provide high-quality tinplate, special lacquer quality, and perfect manufacturing. We can even design the bottom for your specific needs. Contact us for details!

Diameter: 62.5mm/209#

Shell Material: Tinplate

Design: FA

Application: Dairy products, Nut, Candy, Spices, Fruit, Vegetable, Seafood, Meat, Pet food, etc.

Customization: Printing.

-

Food and beverage aluminum peel off end POE 209

Dry foods require special handling before consumption. Milk powder packaging first adopted the peel-off end. Dry food needs to be sealed to keep the product fresh until opened and to protect it from light and moisture.

To achieve these goals, peel of end packaging is perfect. It protects food from the elements while maintaining its nutritional value. Also, when stacked, the peel off end allows space between cans without creasing or damaging them.

-

Food and beverage aluminum peel off end POE 211

Beverages packaged in peel off cans are easy to use and keep clean. Through this kind of closure, it can ensure that the product is safe and secure during storage and transportation without leakage or deterioration. Peel off security reinforcement ensures users can easily access the can end without worrying about safety. This type of can end is very durable. Not only that, but it is also effective in content preservation. Also, it allows food to be stored for a longer time.

-

Food and beverage aluminum peel off end POE 300

When people use traditional easy-open ends, they inevitably run the risk of being injured by the sharp edges of the can end. However, the peel off ends more than make up for this deficiency. Due to their soft texture, the peel off cans are easy to pull apart while ensuring the safety of the user. Also, since their materials are safe, people don’t need to worry about whether they will affect the edibility of canned food.

-

Food and beverage aluminum peel off end POE 305

Food processors can use Peel Off End to improve convenience, protect product freshness and create brand differentiation. Peel Off End offers quick and easy removal and consists of thin, flexible panels heat-sealed to a rigid steel or aluminum ring. Consumers just need to grasp the small tab on the lid and open the package with a simple and smooth gesture, these ends make it easier and quicker for consumers to open food cans.

-

Food and beverage aluminum peel off end POE 307

The peel off end is a packaging solution that can be used for a variety of products because it has easy-to-open suggestions. It comes in different sizes, with an inner ring of D or O shape and an outer ring of square or round. The peel off ends were originally used for canned milk powder packaging. Nowadays, you can find this opening on vegetables, coffee, meat, fruit seafood and many other types of food packaging, such as easy-to-open can ends.

-

Food and beverage aluminum peel off end POE 307

In recent years, Peel off end has become a modern and commonly used product, especially for dry-packed products. The can end features a tinplate or aluminum lid heat-sealed with aluminum foil. It helps create an easy way for the consumer to open or peel off without having to deal with a can opener and without too much trouble. As a result, many packagers are converting their top lids to peel-off ends because the performance of the can ends is consistent, safe, and convenient for consumers.