Peel off lid

-

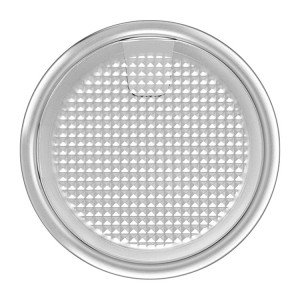

Food and beverage aluminum peel off end POE 309

This Peel Off End is the latest innovation in metal end. It starts with the same process as normal can end making, cutting in the middle of the end to make safe crimp, seal, and embossing with aluminum foil. Such products are suitable for children, women, and the elderly. It has a small thickness, good quality, and saves natural resources. After consumers open the can, it will not cause environmental pollution in case of discarding.

-

Food and beverage aluminum peel off end POE 112

The base of the Peel off end is made of aluminum or tinplate as the tear section and is covered with aluminum foil or a composite membrane. The peel off end is lightweight and safe. Innovations in the industry are also working to make it a more sustainable packaging solution. Just because it’s easy to open doesn’t mean it’s unsafe. This type of can end is used for packaging various products, such as liquid, powder, and solid food. Therefore, although its processing is practical, its storage is highly secure.

-

Food and beverage aluminum peel off end POE 311

The Peel off end (lid) is a form of metal packaging with high airtightness and certain pressure resistance, which is used for food can packaging. The base material is made of tinplate or aluminum, punched, brushed, crimped, and can be opened safely after opening.

-

Food and beverage aluminum peel off end POE 401

Peel off ends have become a more attractive and consumer-friendly alternative to traditional can ends. We offer flexible, convenient and extremely economical solutions for a two-piece and three-piece can packaging, this product can be suitable for both retortable and non-retortable processes, differentiating our customers’ products in the market. Our peel-off ends are easy to use with existing seamer and can be integrated into existing can filling and packaging lines.

-

Food and beverage aluminum peel off end POE 502

Looking for an easy-open lid that will keep your food safe and secure? Try the aluminum peel off end! This innovative packaging is easy to open and guarantees that your product has not been tampered with. Plus, the thin aluminum membrane makes it a breeze to access whatever’s inside. Be sure to try the aluminum peel off end today! Look no further than the Aluminum Peel-Off Lid! Unlike other types of lids, our Peel-Off lid is extremely durable and features an anti-cutting mechanism to keep your food safe. Plus, our lid is perfect for a variety of food types, including dry tea, coffee, milk powder, coffee powder, dairy products, nuts, and more!

-

Food and beverage aluminum peel off end POE 603

Food and Beverage Aluminum Peel Off Ends are tightly protected against moisture, UV, and gas and are ideal for bulk products such as milk powder, spices, supplements, coffee, or tea. With removable aluminum film, smooth or corrugated film. The peelable can end leaves a blunt edge after opening, which makes the can end particularly safe after opening and offers excellent product resistance. Now, peel off end is widely used in food packaging.

-

Food and beverage aluminum peel off end POE 209

Dry foods require special handling before consumption. Milk powder packaging first adopted the peel-off end. Dry food needs to be sealed to keep the product fresh until opened and to protect it from light and moisture.

To achieve these goals, peel of end packaging is perfect. It protects food from the elements while maintaining its nutritional value. Also, when stacked, the peel off end allows space between cans without creasing or damaging them.

-

Food and beverage aluminum peel off end POE 211

Types of Peel Off Ends are as follows:

Peel off end for dry powder packaging does not have high-temperature sterilization technology, and is used in canned foods such as milk powder and snack foods, which is relatively common in the market.

The retort peel off end has the characteristics of high-temperature sterilization. It can be used in canned food such as meat, and the consumer can easily cook the food.

-

Food and beverage aluminum peel off end POE 211

Beverages packaged in peel off cans are easy to use and keep clean. Through this kind of closure, it can ensure that the product is safe and secure during storage and transportation without leakage or deterioration. Peel off security reinforcement ensures users can easily access the can end without worrying about safety. This type of can end is very durable. Not only that, but it is also effective in content preservation. Also, it allows food to be stored for a longer time.

-

Food and beverage aluminum peel off end POE 209

The easy peel off end with soft foil provides added convenience for consumers. With this type of aluminum can ends, people of all ages can easily pull them open without the help of a can opener. The excellent sealing of the peel off end can also meet the sealing requirements of most foods. It can even be said that the easily peeled end has better sealing performance, thus extending the service life of the food.

-

Food and beverage aluminum peel off end POE 300

When people use traditional easy-open ends, they inevitably run the risk of being injured by the sharp edges of the can end. However, the peel off ends more than make up for this deficiency. Due to their soft texture, the peel off cans are easy to pull apart while ensuring the safety of the user. Also, since their materials are safe, people don’t need to worry about whether they will affect the edibility of canned food.

-

Food and beverage aluminum peel off end POE 305

Food processors can use Peel Off End to improve convenience, protect product freshness and create brand differentiation. Peel Off End offers quick and easy removal and consists of thin, flexible panels heat-sealed to a rigid steel or aluminum ring. Consumers just need to grasp the small tab on the lid and open the package with a simple and smooth gesture, these ends make it easier and quicker for consumers to open food cans.